FBTec®

PACKAGED STP

"A Patented Technology Empaneled by Jal Shakti Ministry"

Introduction:

FBTec® is a Patented and Jal Shakti ministry empanelled technology for wastewater recycle and reuse at source.

Using a fixed media, the units ranging from 5KLD upto 2MLD are modular and movable. The modular units made are designed in a way that we can change / arrange the layouts as per space availability. Even plants upto 2MLD capacity can be installed in areas as small as 25m x 20m. Units upto 100KLD are housed on a single platform with compartmentalized process tank and tertiary treatment.

FBTec® gives a large range of modules where-in space saving is achieved…e.g. we have design for 200KLD, 250KLD and 300KLD and we do not need to go in multiples of a particular capacity like 50KLD or 100KLD.

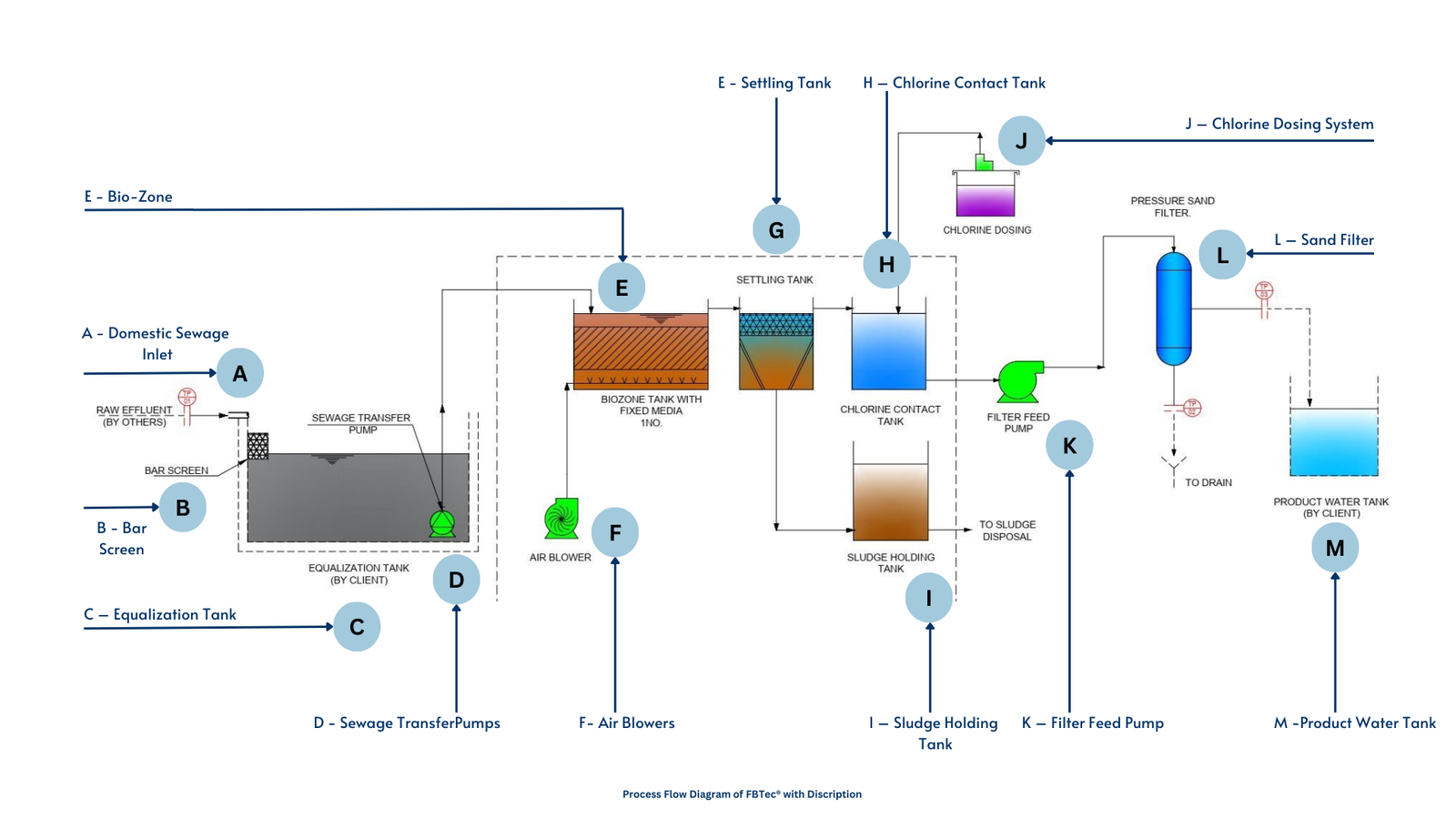

Process Detailing

- Screening and collection of the incoming wastewater

- Providing a uniform flow to the process tank using a pump; we strongly advice against the use of a cutter pump.

- Using a fixed media in the process tank to cultivate bacteria. This provides larger vertical space in a unit area to reduce footprint. Just like we did with our vertical flat systems where-ever we do not have space to expand horizontally.

- The fixed media arrangement in the process tank is placed in such a manner, where the media neither moves nor gets washed away.

- Providing adequate air for BOD as well as NH4 reduction.

- Chlorination for disinfection.

- Sand Filtration is used as a tertiary treatment without Activated Carbon filter. Our R&D has established that carbon filters are a potential breeding ground for bacteria; hence we do not include it in the system.

Each step is elaborated below:

-

01. Screening and collection of the incoming wastewater

The wastewater is collected in a tank; usually called as an equalization tank. 6 mm screen is provided at the inlet of the tank where-in foreign material like clothes, wood, plastic…. etc is separated from the wastewater and taken out of the system.

-

02. Pumping the wastewater to the process tank:

The screened wastewater collected in the equalization tank is pumped at a uniform flow to the process tank. Here, we do not use cutter pump to avoid non-bio-degradable material getting into the process tank. A cutter pump would cut non-bio-degradable material like clothes, plastic ..etc into small pieces and put into the process tank where we grow bacteria; which will hamper the bacteria growth.

-

03. Process tank – Bio Zone:

The biological treatment of BOD and complete nitrification of ammoniacal nitrogen shall takes place in this tank. This process consists of growth of different bacteria/ micro-organism on the fixed media. Microbiological growth occurs by utilizing organic compounds and ammoniacal nitrogen. The micro-organism absorbs and oxidizes organic contaminants via biological oxidation. The process utilise the nutrients in wastewater (i.e. nitrogen and phosphorus) in addition to organic contaminants for healthy cell synthesis to occur. The denitrification shall also occur in this tank.

-

4. Air Requirements in the Bio Zone tank:

Air calculation caters for BOD load (0.6 kg O2/kg), Nitrification (4.5 kg O2/kg NH4), Water levels and Bacteria survival.

-

5. Nitrification and Denitrification:

All three zones, aerobic, anaerobic and anoxic are formed in the same tank. Following reactions take place in it. Anoxic Zone: NH4 - (Air does Nitrification) - NO3 - (Anoxic Zone uses 02 for denitrification). This reduces BOD and eliminates smell.

-

6. Clarification / Tube settler:

Tube Settler shall remove the suspended solids from liquor with Suspended Solids overflown from biozone tank. The solids shall be and the supernatant shall overflow into chlorine contact tank. The sludge shall settle at the hopper bottom of tank of clarifier. The settling tank is provided with parallel plates to enhance the settling in lesser space.

-

7. Chlorine contact tank:

A simple tank with a residence time of 30 minutes or more is provided. NaOCL is dosed in this tank for disinfection.

-

8. Sludge Holding tank:

A tank with a capacity to hold sludge generated for at least 5 days period is provided.

-

9. Chlorine Dosing System:

A hypochlorite doing system consisting of a dosing tank and a dosing pump is provided.

-

10. Sand Filter:

As a tertiary treatment, a sand filter with 4 layers of sand is provided. The sand distribution is as below:

- Pebble Size (25 – 50 mm) : One-layer; 100 to 200 mm at the bottom; depending on vessel size.

- Pebble Size (12 – 25 mm) : One-layer; 200 to 300 mm depending on the vessel.

- Pebble Size (6 – 12 mm) : One-layer; 200 to 300 mm depending on the vessel size.

- Fine Sand : One-layer 100 to 200 mm depending on the vessel size at the top

FBTec® Performance Chart

| SN | Parameter | UOM | Inlet | Outlet |

|---|---|---|---|---|

| 1 | Ph | 6 – 8 | 6 – 8 | |

| 2 | BOD | Mg/lit | 300 | 10 |

| 3 | COD | Mg/lit | 500 | 100 |

| 4 | TSS | Mg/lit | 100 | 10 |

| 5 | Oil/Grease | Mg/lit | 5 to 10 | Nil |

| 6 | T-N | Mg/lit | 50 | 10 |

Unit Economics

Less Space Required

Lower Power Consumption

Modular & Movable Design

Minimum Site Work

Fixed Media-No Media Replacement Required

Minimum Downtime

Reliable Design

Lower Operating Cost

Minimum Site Work

Works on Single Phase Upto 40KLD

FBTec® Features

1. Low life cycle cost:

FBTec® uses a fixed media which doesn’t need any replacement bringing down the lifecycle cost down to minimum.

Except for bearings replacement in drives at a particular interval, there is no maintenance. Stand-by units at all stages with automatic control provided to limit manual interference. Units upto 50 KLD do not need continuous operator.

All the FBTec® units are supplied with in-built tertiary treatment with automation in place. All the units are built and tested at our factory leading to minimum site work.

FBTec® provides a wide range of modules….e.g. 50 KLD and 100 KLD both units are supplied as a one piece or single unit. We do not need to go for two units of 50 KLD to make a 100 KLD unit.

FBTec® is developed keeping in mind Indian conditions. Keeping in mind the lack of space, skilled manpower and three phase power supply in rural areas, FBTec® has lesser foot-print than conventional technologies, an unskilled personnel can operate the unit and units upto 40 KLD operate on single phase power supply making it the ideal technology for rural areas or in urban areas at places like public toilets, religious places or where three phase power supply may not be readily available